The Challenge

A successful FOW IAC system design requires more than just electrical capacity—it must seamlessly integrate with the floating platforms, withstand extreme environmental forces, and optimise the offshore layout to prevent interference with neighbouring subsea assets. Additionally, selecting the right cable cross-section and configuration is crucial for both technical performance and cost-effectiveness. The project demanded a rigorous approach to analysis, ensuring that every aspect, from installation to long-term operational stability, was meticulously considered. The main challenge within the procurement scope is the industry’s early stage, which made reliable information scarce. Additionally, component suppliers are highly protective of their designs and do not publicly disclose pricing.

The Solution

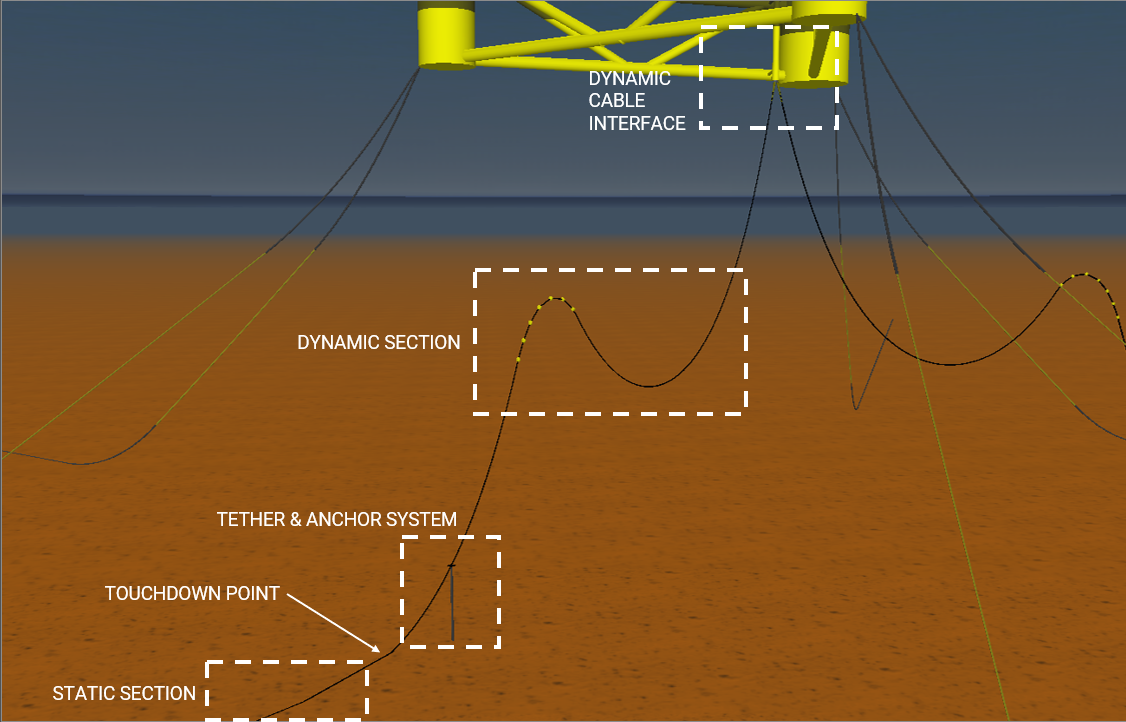

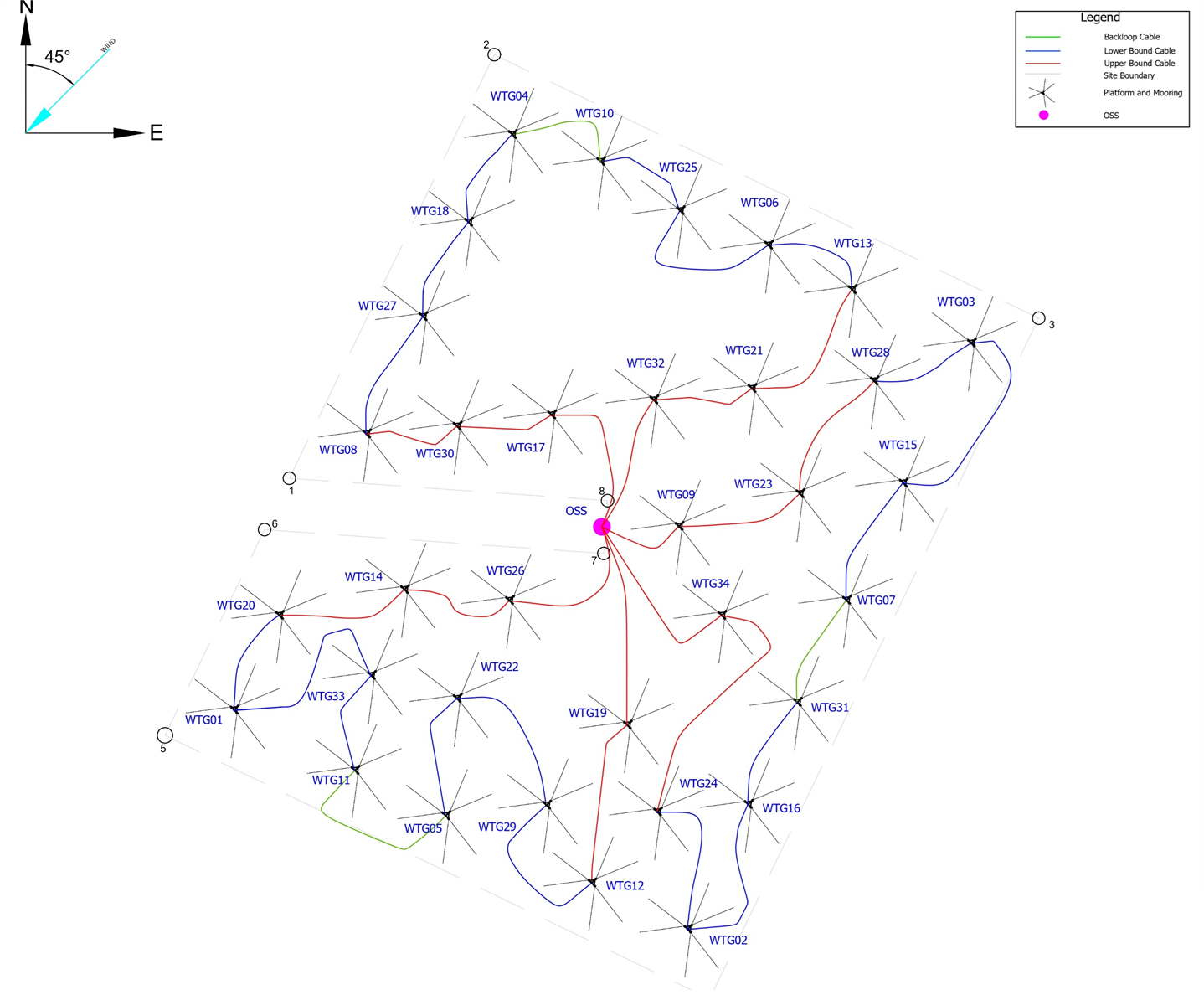

Leveraging advanced simulations and detailed engineering assessments, Tadek explored multiple cable configurations, testing their resilience against real-world offshore conditions. A lazy wave design emerged as the optimal solution—offering the necessary motion decoupling while minimizing installation complexity. Using in-house cable cross-section design software, PreCAB, the team developed two tailored 66kV inter-array cable designs for different capacities, fine-tuning its cross-section to align with IEC standards and supplier capabilities. The array layout was then optimised to ensure sufficient clearance between cables, moorings, and anchors, reducing installation risks. Throughout the process, Tadek engaged suppliers for procurement insights, refining the cost model to align with the project’s financial and technical objectives.

The Outcome

The final design validated the lazy wave configuration as a robust, long-term solution, maintaining cable integrity under extreme conditions while optimising material usage. Alternative configurations demanded greater cost and installation complexity while offering only marginal gains. By strategically using lower-capacity cables for the first few in the string, significant cost savings were achieved without compromising performance. The refined array layout facilitated a safer, more efficient installation process, mitigating the risk of cable clashes. Through precise engineering and strategic procurement, Tadek delivered a comprehensive pre-FEED report that set a strong foundation for the project’s next phase—ensuring both technical excellence and commercial viability.

“Working with Tadek has been a real pleasure; they are a team of highly skilled and knowledgeable professionals, with whom it was easy to establish an open and reliable line of communication.

Tadek helped us successfully deliver the IAC part of a floating wind preFEED project, that was a first-off for us. I very much appreciated Tadek’s pragmatic approach and will surely select them again in the future.”

“Working with Tadek has been a real pleasure; they are a team of highly skilled and knowledgeable professionals, with whom it was easy to establish an open and reliable line of communication.

Tadek helped us successfully deliver the IAC part of a floating wind preFEED project, that was a first-off for us. I very much appreciated Tadek’s pragmatic approach and will surely select them again in the future.”

Gloria Vittadini, Project Manager Floating Wind

Maersk Supply Service