Since 2010 the team have developed designs, and installation solutions for a vast range of floating systems and have been offshore to manage these installs.

Our Expertise

A floating system is complex and interconnected. Tadek naval architects, analysts and project engineers work to achieve optimised and comparative solutions for a range of scenarios of the complete system.

These are developed whilst considering the full life cycle, encompassing transport, assembly, tow out, operation, and survival.

Born from real-life experiences, the team enable investment decisions and proper assessment of project feasibility.

Floating System Modelling

Interconnected modelling and life cycle considerations for all floating plant.

FOW System Design

Model, assess, optimise, compare. Engineering depth for investment decisions.

FOW Mooring Design

Efficient, robust, installable mooring solutions. Cost modelling and technical excellence.

Dynamic Cable & Umbilical System Design

Proven and robust O&G solutions by industry professionals, optimised for FOW.

Floating System Installation Design

O&G and FOW project and site experiences, enhanced by nearly every MRE device install since 2010.

Floating System Modelling

As naval analysis engineers, we model hydrodynamic systems to assess overall capability under operational and extreme environmental conditions. We present the assessment of these systems in detailed design reports, sufficient for approval by third party approval and classification bodies. There are a number of stages in the modelling process:

- Basis of Design

- Hydrostatic Analysis

- Hydrodynamic Analysis

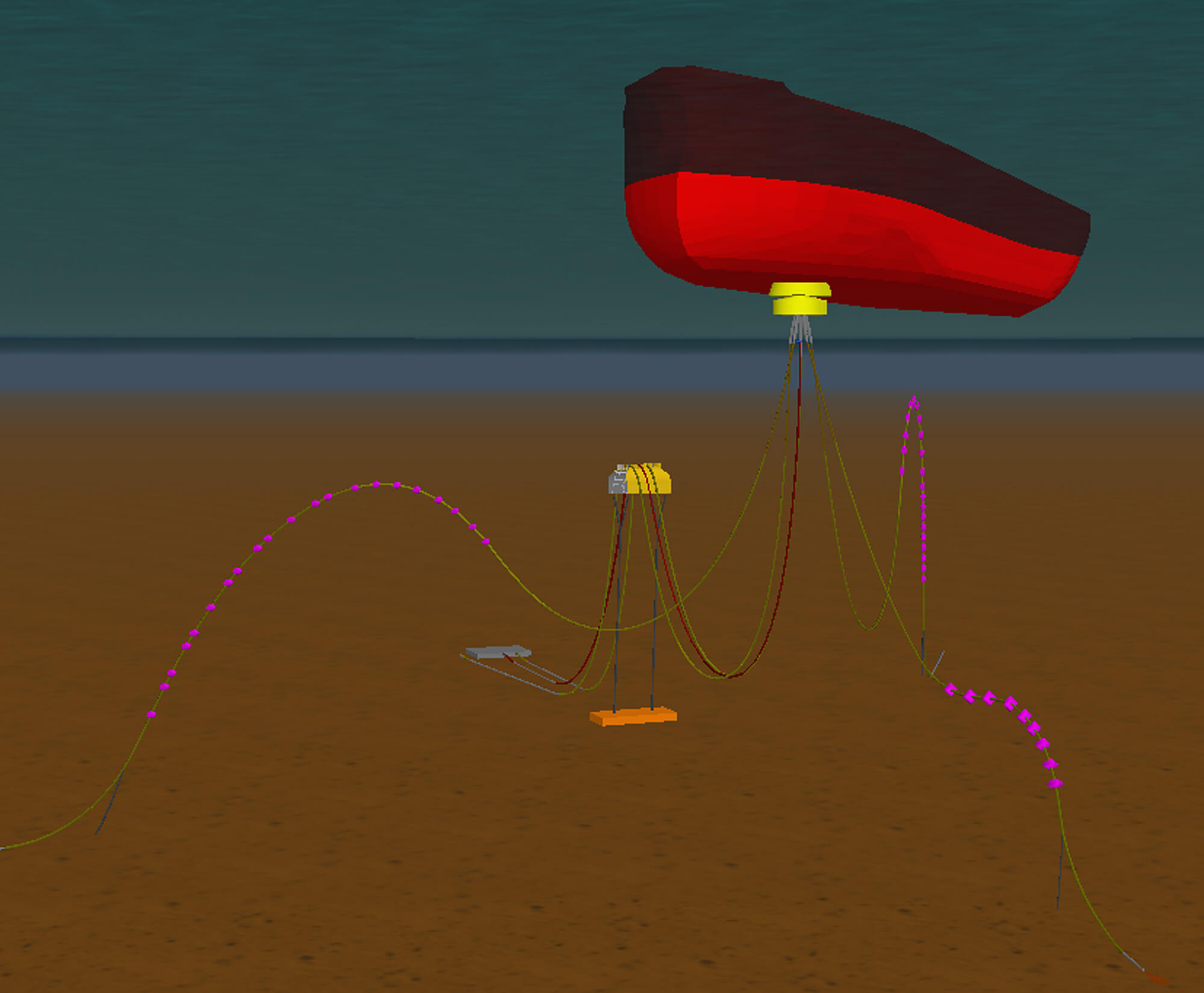

- Mooring System Modelling

- Cable/Umbilical System Modelling

- Installation & Operations

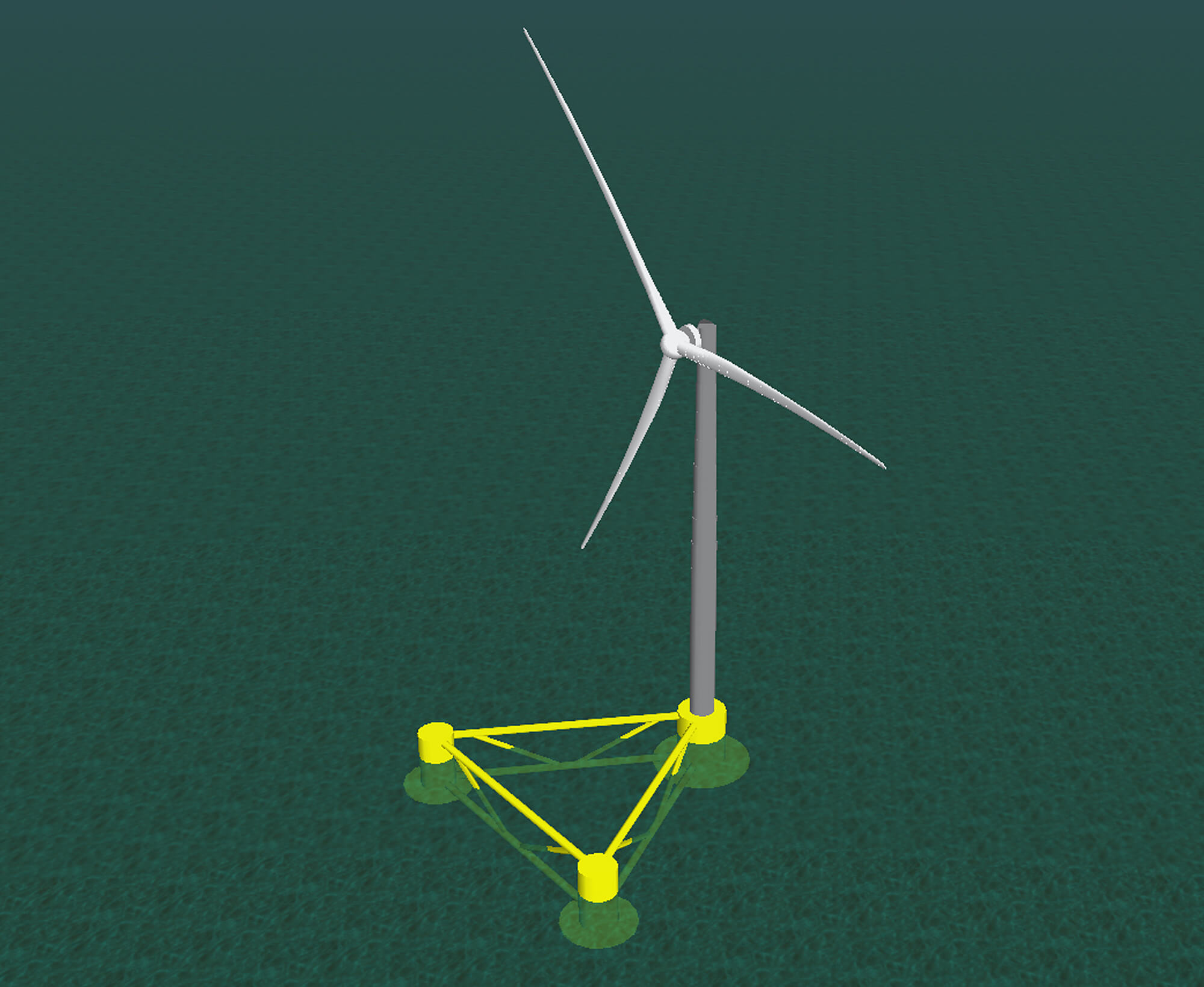

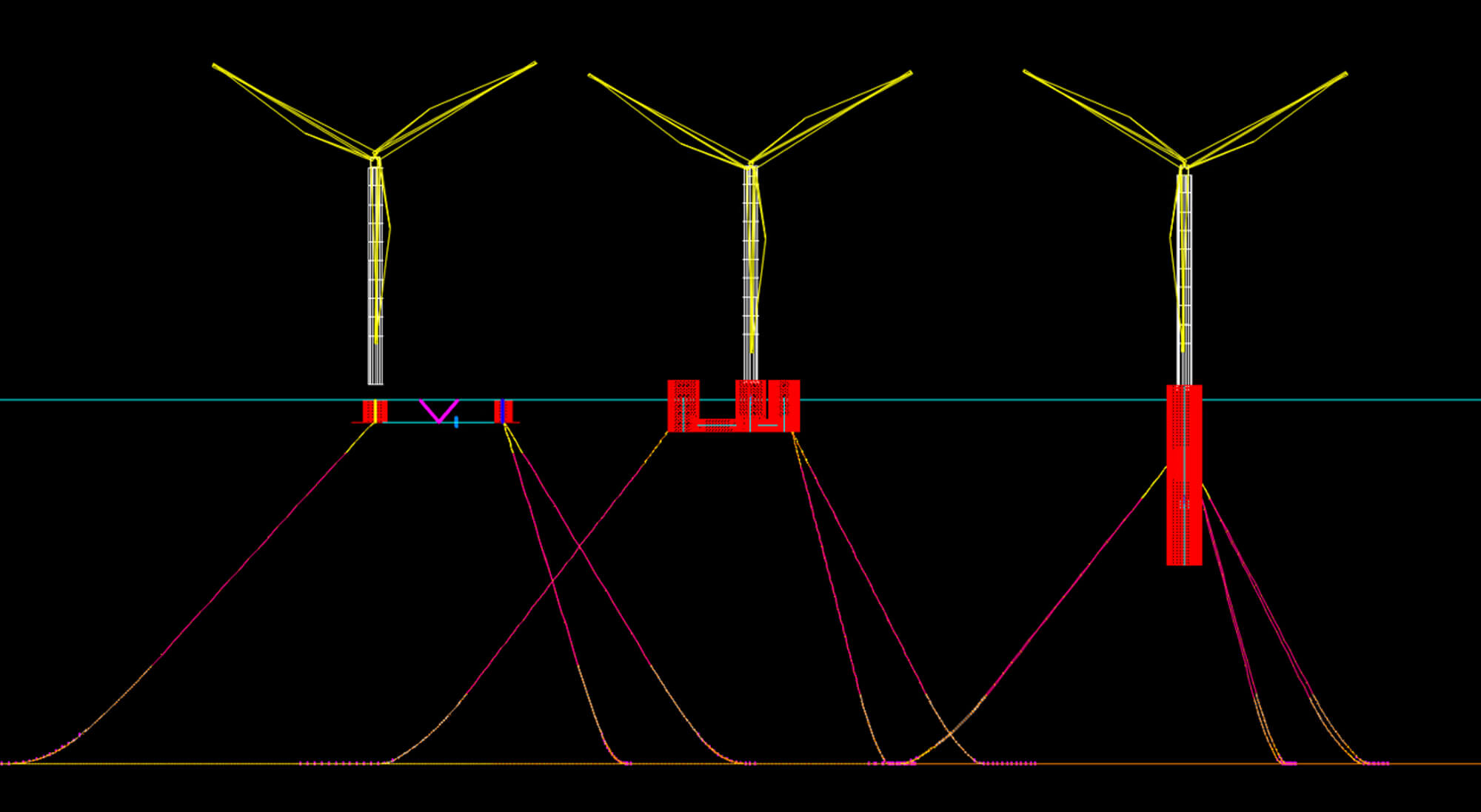

FOW System Design

Tadek naval architects combine hydrostatic and structural analysis for FOW technology and site developers answers to key questions like:

- Relationship between FOWT power scaling to structural mass scaling?

- Performance comparison between FOWT archetypes?

- How is size affected by Hs?

- Can draft be optimised for hydrodynamic performance and to meet Assembly & O&M requirements?

FOW Mooring Design

Tadek naval architects develop models for a range of FOW archetypes and environments.

- How does layout, cost and risk change from 70m to 500m WD and beyond?

- What is the impact of traditional and innovative materials/device properties?

- Mooring system installation feasibility, process and cost

Dynamic Cable & Umbilical System Design

Experiences in both high value, high risk O&G umbilical design for permanent works, as well as floating MRE and FOW are combined within in-house tools to carry out dynamic system analysis for any cable, umbilical or riser system, resulting from vessel motion, waves and current.

Tadek have experience designing dynamic cable systems for FOW. Various configurations (e.g. lazy, pliant, steep wave, etc.) are assessed from platform to seabed, as well as IAC routing, to present operational, cost and risk analysis, as well as answering questions such as: how is fatigue life impacted by configuration selection?

The work includes cross-section design supported by an in-house software (PreCAB) . PreCAB utilises well established equations and industry standards to deliver a cross section design sufficient and valid for FEED design and project cost estimation prior to more detailed cable manufacturer data.

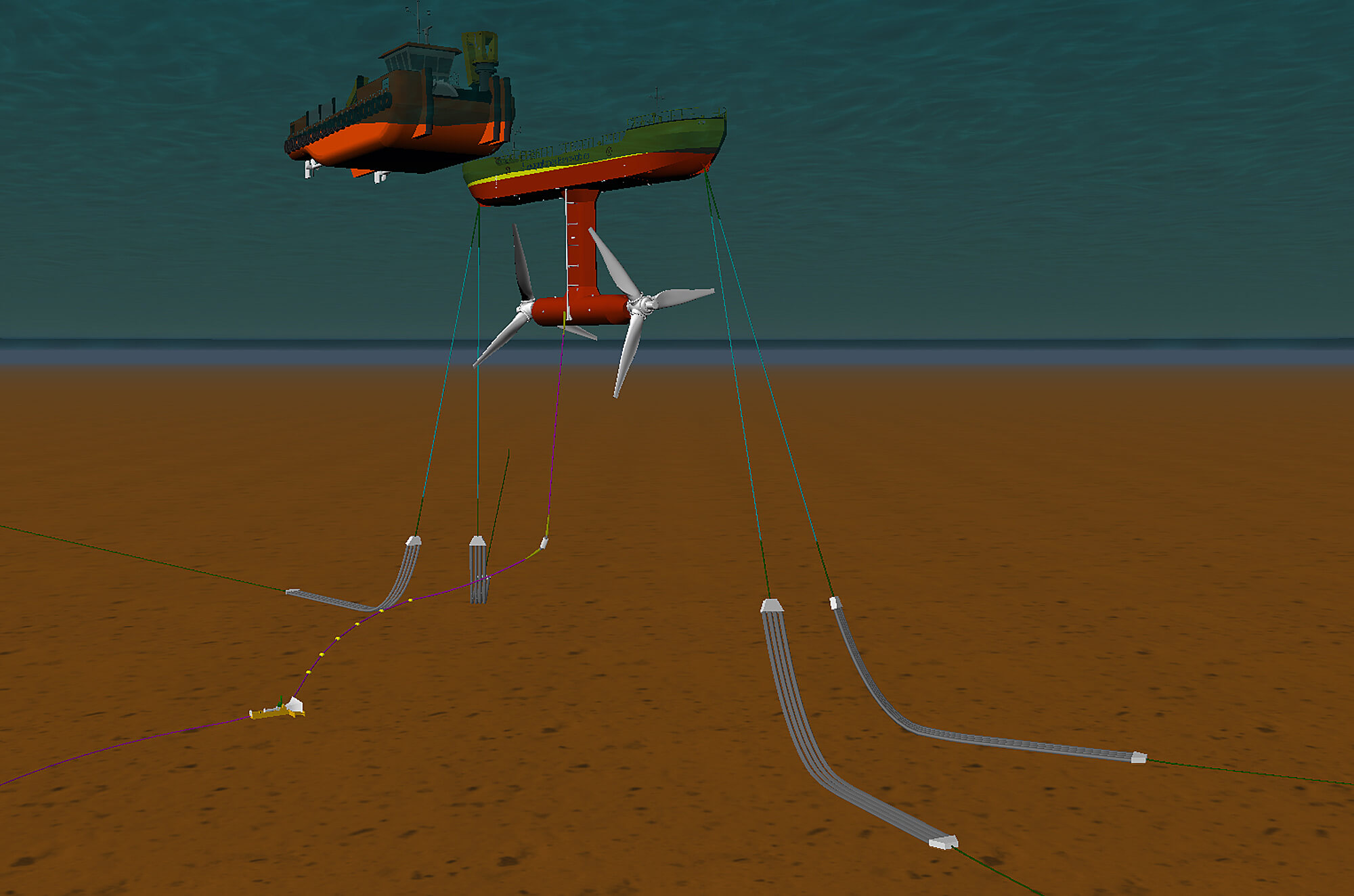

Floating System Installation Design

Tadek analysts and project engineers work together to optimise designs for optimal and efficient hook-up of a range of assets, amongst them FOWTs, FPSOs, and floating MRE.

These solutions are born from a range of practical offshore experiences hooking up a range of assets.

The team can therefore both engineer and develop various procurement and operational deliverables to enable a complete picture of the system and resulting costs and risks.