The Challenge

The main challenge of inter-array cable installation analysis is that fields include a diverse array of cable types, CPS, and environmental conditions, which require a comprehensive set of analysis scenarios. Sometimes data is not available for all components and environments. Each scope generates thousands of simulations and results, but the operation team are only interested in the key parameters and operability tables.

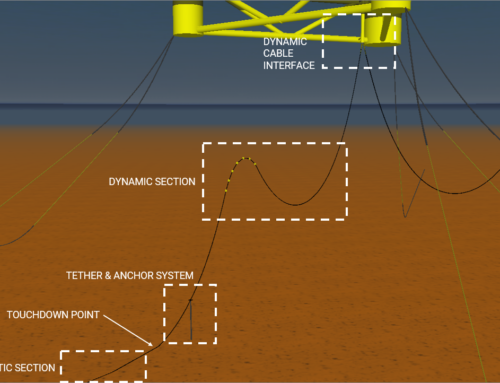

Cable interaction with monopile interfaces such as J-tubes and apertures can be complex, which makes it difficult to assess the capacity of equipment required. Assessments of vessel motions, cable loadout, vessel mooring, and vessel transit are often needed as well.

The Solution

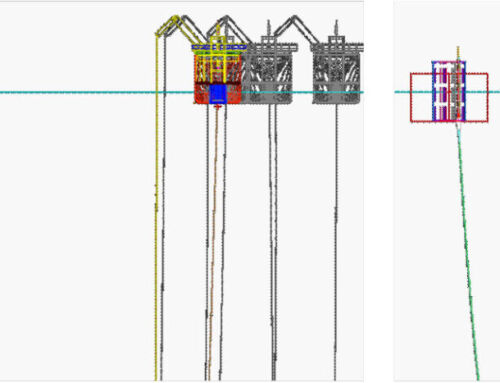

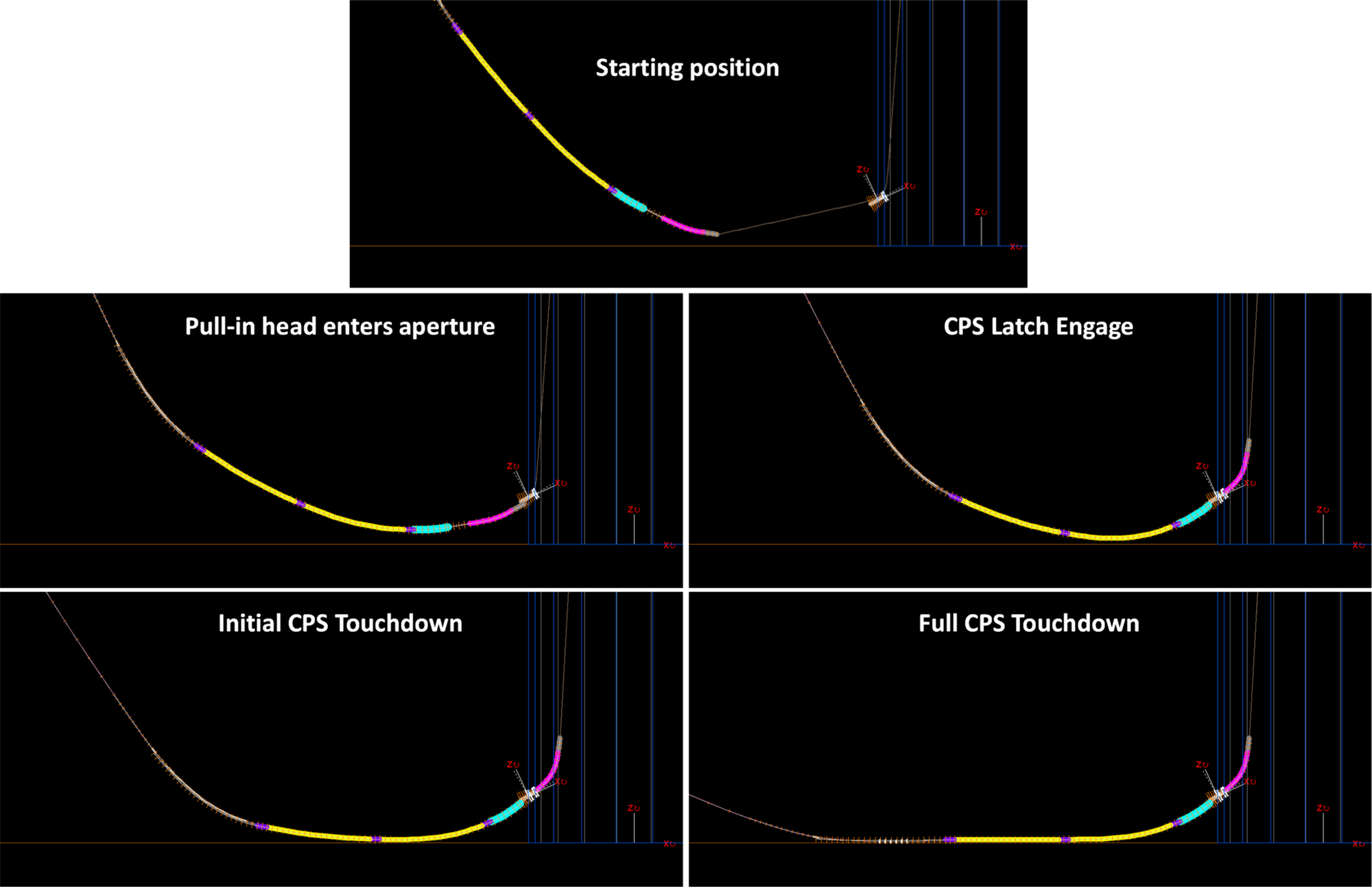

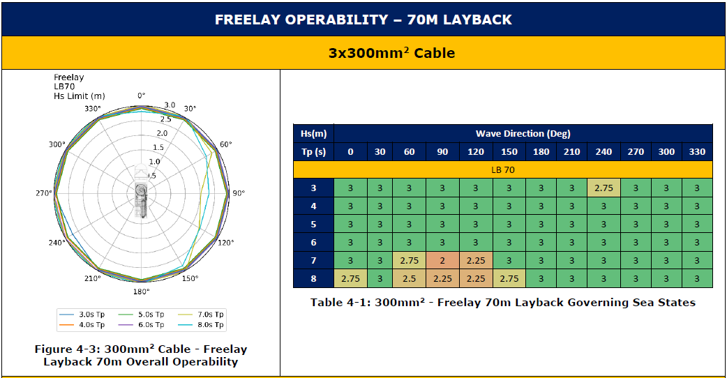

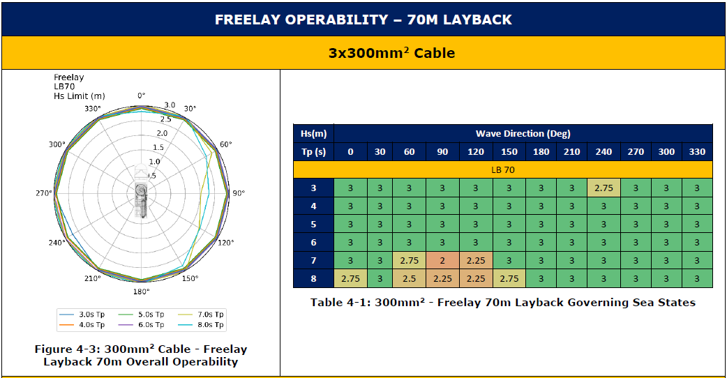

Tadek performed a comprehensive transient analysis of the 1st and 2nd end CPS and cable pull-in through J-tubes and apertures, optimizing each stage to prevent product damage and ensure operations remained within equipment limits. Key parameters were presented in lay tables, while critical stages were run dynamically to generate operability rosettes.

Collaborating closely with the project team, Tadek developed effective and reliable deliverables that streamlined operations. Their extensive experience in cable installation, combined with a comprehensive data catalogue, ensured timely execution even in cases of missing data.

For cable repair scenarios, accurate hydrodynamic models were rapidly generated for a range of vessels and loading conditions, including those without prior operational experience. Quayside mooring analysis were performed for multiple ports and layouts, ensuring full compliance with OCIMF MEG4 standards.

The Solution

Tadek performed a comprehensive transient analysis of the 1st and 2nd end CPS and cable pull-in through J-tubes and apertures, optimizing each stage to prevent product damage and ensure operations remained within equipment limits. Key parameters were presented in lay tables, while critical stages were run dynamically to generate operability rosettes.

Collaborating closely with the project team, Tadek developed effective and reliable deliverables that streamlined operations. Their extensive experience in cable installation, combined with a comprehensive data catalogue, ensured timely execution even in cases of missing data.

For cable repair scenarios, accurate hydrodynamic models were rapidly generated for a range of vessels and loading conditions, including those without prior operational experience. Quayside mooring analysis were performed for multiple ports and layouts, ensuring full compliance with OCIMF MEG4 standards.

The Outcome

Tadek collaborated with the project engineering team to deliver documents that were easy to follow and useful to the offshore team. Each document featured clear schematics, lay tables and operability rosettes for a range of environmental conditions. During the engineering phase, Tadek used the analysis results to design and verify the suitability of various equipment.

The precision of our J-tube pull-in and cable lay analyses enabled safe, efficient installation processes across diverse depths and turbine locations, streamlining operational procedures and ensuring maximum uptime.

Through meticulous planning and technical insights, Tadek helped deliver an installation that surpassed safety and performance expectations. By enhancing both operational efficiency and risk management, Tadek’s contribution proved essential in the success of these projects.

The Outcome

Tadek collaborated with the project engineering team to deliver documents that were easy to follow and useful to the offshore team. Each document featured clear schematics, lay tables and operability rosettes for a range of environmental conditions. During the engineering phase, Tadek used the analysis results to design and verify the suitability of various equipment.

The precision of our J-tube pull-in and cable lay analyses enabled safe, efficient installation processes across diverse depths and turbine locations, streamlining operational procedures and ensuring maximum uptime.

Through meticulous planning and technical insights, Tadek helped deliver an installation that surpassed safety and performance expectations. By enhancing both operational efficiency and risk management, Tadek’s contribution proved essential in the success of these projects.

“This scope utilised Tadek’s capability and experience with cable installation and repair operations to produce excellent deliverables to support offshore operations. The analysis engineers adapted existing scripts to generate and post-process a large batch of dynamic analysis for a range of cables, CPS and environmental conditions.”

Projects Team

Tadek Limited